DELTA DELAGE havs 40 years’ experience for unparalleled performance

The successive integration of the Auxim and Delta Delage brands gives Ades Technologies the benefit of 40 years’ experience in hydraulic valve high-pressure solutions.

ADES Technologies was a pioneer in this field, introducing “between-flange” solutions from the outset, which were adapted to the SAE standard and floating sealing, which have often been copied but still have the technological lead. In addition, special care has also been taken in the design of high-pressure valves up to very large sizes.

Under the Delta Delage brand, these valves with special seals are among the best-performing valves on the market.

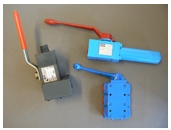

Delta Delage Products

RD3

DN: from 6 to 50

Pressure from 200 to 350 bars

Impact: Manufacturer

HP3

DN: from 15 to 100

Pressure: See ISO standard 6162-1

Impact: SAE

HP6

DN: from 15 to 50

Pressure: See ISO standard 6162-2, 420 bars

Impact: SAE

H352 and H354

DN: 40, 50, 65, 80

Pressure: 350 bars

Impact: Cetop/PN400 or Manufacturer (DN40 and 50)

RD7

DN: 6 to 40

Pressure: 630 bars

Impact: proprietary

Multi-way manifold

DN: from 15 to 50

Pressure: See ISO standard 6162-1 and 6162-2

Assembly: between flanges or new version on base

Impact: SAE or Manufacturer (on base)

Materials

Sleeve: phosphate-treated steel, stainless steel (or surface treatments on demand)

Ball: Stainless steel

Sealing: Polyacétal

Seals: Buna, FKM (Viton), EPDM, Specific

Handle: forged steel

Temperature range: according to seals

Assembly options

In-line (between flanges)

Flanged laterally impact (with or without retaining plate)

On base (Manifold)

Twinned.

Connection

Any type of flange (BW, BSPP, SW etc) SAE impact

Cetop or proprietary (RD)

Options

Micro contact (electric or induction)

Can be padlocked

Locked

Type of drive (pneumatic, electric, hydraulic)

Repair kit.

Type of circuit

Oil

Air

Nitrogen

Water

Fuel

Gas

Aeronautical oil

Esters-phosphates

Etc

Product benefits

Low operating torque including high DN at high pressure

High pressure/high DN/Operating torque

Flange connection (standardized SAE or manufacturer RD)

Easy fitting and removal with flange connection, without moving the pipework

Small spatial requirement with built-in connections

No more stacking of connectors or risk of leaks

Integral passage

High-pressure resistance (delta P maintained)

Manufacturer’s plate (traceability)

Individually assembled and tested

Reliable performance over time

Low operating costs

Proven design (dating from the 1960s for the RDs and 1980s for the HPs), based on hydraulic know-how.

Experience in difficult environments where reliability is required

Products

DELTA DELAGE LOW PRESSURE VALVE RA 20

- DN: from 8 to 50

- Pressure: 10 bars

- Connection: BSPP, in-line mounting

- Temperature: -25° to +70° (low-temperature seals available)

- Options: vented, handle position, kit de maintenance, other seals

?

Materials

- Sleeve: phosphate-treated steel or GS cast iron

- Rotating cylinder: brass or chemical nickel plating

- Handle: steel or cast iron

?

Options

- Micro contact

- Twinning

- Custom valves made to order

DELTA DELAGE CHECK VALVE The benchmark for check valves

ADELTA DELAGE s for high-pressure valves, the high-pressure check valves range complies with SAE 3000 & 6000 (ISO standard 6162-1 & ISO 6162-2). The SAE check valve allows assembly between flanges or flanged against a block (smooth or tapped holes). It is also possible to adapt the tapping to the needs of different hydraulic systems.

Products

AR3

DN: from 10 to 50

Pressure from 210 bars

Impact: ISO 6162-1

AR6

DN: from 15 to 50

Pressure: 420 bars

Impact: ISO 6162-2

Materials

Sleeve: phosphate-treated steel, Stainless steel (or surface treatment)

Valve: Steel or Stainless steel

Seals: Buna, FKM (Viton), EPDM.

Option

Tapping from 0.5 to 5 bars in standard version, or custom

In-line (between flanges/tapped holes)

Laterally flanged impact (with or without retaining plate/smooth hole)

Seals at inlet and/or outlet end

Connection

Any type of SAE impact flange

Type of circuit

Hydraulic

Product benefits

Standardized SAE connection

Easy to fit and remove

Small space requirement with built-in connections

High-pressure resistance (delta P maintained)

Manufacturer’s plate (traceability)

Performance over time

Low operating costs

Experience in difficult environments where reliability is required.

DELTA DELAGE ADES Technologies, a key European player Since the early 1970s, Ades Technologies (Delta Delage) has developed connection systems for low-pressure hydraulic systems. The range has been enriched with a number of innovations; in particular those concerning the protection of people ("jet deflector" systems). After acquiring machines and tools from Forges de la Becque, Ades Technologies has become a first-class player in Europe by mass-producing SAE 3000 and SAE 6000 flanges. Quality excellence Ades Technologies is a member of the ISO commission and actively helps improve standards. BW SW SWR Tapped Threaded Blocks Blocks with BW, SW ends Deflector Option BSPP NPT BSPP BSP Conical NPT "E" "L" "T" "X" ISO 6162-1 (SAE 3000) X X X X X X X X X X X X X X ISO 6162-2 (SAE 6000) X X X X X X X X X X X X X X ISO 6164–1 (PN 250)-CETOP X X X X X - X X X X X X - - ISO 6164-2 (PN 400) 6 CETOP X - X X X - X X - - - - - - PN 600 X - - - - - - - - - - - - X

DELTA DELAGE Low- pressure Auxim connectors: tried-and tested products Auxim connectors are proven products in demanding applications such as railway rolling stock braking systems. They are also very efficient in other sectors. Navy: water system (washing, domestic, soft and salt water cooling systems, scupper circuit etc), air circuit (inert gas, compressed air, air release, probe and filling, steam and condensate), oil transport etc Chemicals and pharmaceuticals: for all types of fluid transportation with adapted elastic seals. Can be mounted on glass tubes Other industries: nuclear (radio protection), engines (diesel, thermal, gas), all low and high temperature applications, multiple fluids (studies required) etc Tried-and-tested connectors Auxim Rx connectors are designed to: join together smooth, rigid or flexible pipes ? 1/8 to ? 2” and ? 6 to ? 57 mm (? tube’s outer diameter) simply with the aid of two open-end spanners, avoid the need to thread, solder or splay the tubes or fit a sealing ring, withstand service pressures of 600 bars (? 6 mm) to 50 bars (? 57 mm) according to diameter. Product benefits When fitting: Axial trimming for each tube ≥ 3° Standard or thin-walled tubes can be used with higher tolerances for outer diameter Tubes of different materials can be connected Excellent vibration, pressure and temperature resistance (CETIM trial no. 6019718 /661/4a of 20/11/92) In use: Spatial requirement: smaller bending radius Safe because it is fully sealed, reliable thanks to its resistance to vibrations and durability commensurate with the service life of the rolling stock. For maintenance: The same seals can be used when dismantling and reassembling, without the need to cut the tube. No deformation of tube or alteration of surface state, no preparation (threading, crimping, soldering etc) required Easy to take apart and reassemble (union slides onto the tube) Low operating cost and low maintenance Specifications Type of connectors: straight union, stud male/female/reducing union, elbow, male elbow, Tee, Male/reducing tee, adjustable, multi-directional, cross, Y branch, bulkhead, male/female/reducing union adaptor, plug etc Available materials: steel, brass, stainless steel aluminium Sleeve coating: electrophoresis, phosphate treatment, white galvanized (without hexavalent chromium), Clamping device: steel, brass, stainless steel, aluminium, plastic Seal: NBR, EPDM, Viton, Silicon, and "low temperature" Layout: cylindrical/conical gas, NPT, ISO metric Type of circuit: Compressed air, butane, propane etc; Water and steam, ozone etc; Hydrocarbons, liquid or gaseous etc Quality excellence Auxim Rx connectors are made to ISO 9001 standard Ed.2000.

DELTA DELAGE High-precision flow dividers The rotating gear flow divider is the ideal device for fully synchronizing cylinders. Very easy to use and finished to a very high standard, ADES Technologies’ flow divider will satisfy the most exacting requirements for precision and reliability. Materials Sleeve: high-strength semi-steel Gear: treated, ground and polished stainless steel Dimension and pressure Capacities from 2 to 30 cm3/T Input pressure of 17 bars at 350 bars as standard Type of circuit Mineral oil as standard or glycol water Applications Any application requiring full synchronization of cylinders (2% variance, compensating speed 1/10th of a second) and great reliability. Product benefits High in-flow rate possible Precision: 98% efficiency at an ideal rotation speed of 1500 rpm Built-in pressure controller, by section Leaks are impossible between sections Regular flow rate guaranteed Compensating speed between cylinder in the order of 1/10th of a second* Can be used as pressure intensifier Reliability: average service life of 35000 hours* (*not contractually binding)